Overview

Being a qualified and honest glassware supplier, Sunny glassware always treat the quality as the highest priority to prevent the defective products. We ensure strict quality control not only in our own factory but also in dealing with other SGS, RoHS and REACH qualified factories -by tests and inspections. 100% test is obligatory for every product before delivery. All our business processes are externally verified and certified to the highest standards available - ISO for quality and environmental impact.

Skilled QC Team

| Numbers of QC team | 30 -39 |

| Technical Support |  Sunny glassware own the experienced QA and QC team. Sunny glassware own the experienced QA and QC team. All QC inspectors are well trained before being allowed to start QC. All QC inspectors are well trained before being allowed to start QC. Strict inspection would be conducted from acquiring raw material to finishing the products and completing packaging. Strict inspection would be conducted from acquiring raw material to finishing the products and completing packaging. Every production line is under inspection by professional QCs who will conduct piece by piece inspection. Every production line is under inspection by professional QCs who will conduct piece by piece inspection. |

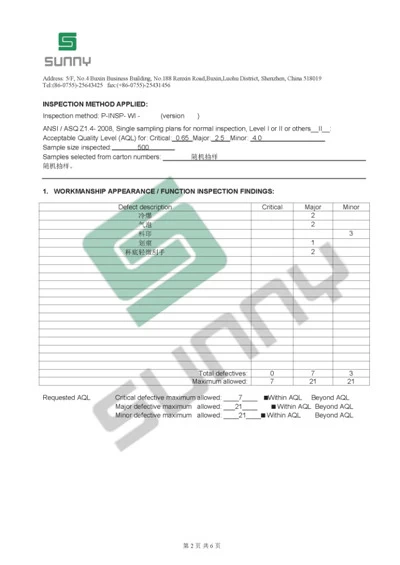

| Procedures | (1) The responsible QC should understand the order lead time and started produce time (2) Confirm the inspection ways to prepare the inspection plan. All the innspection tools such as rulers, label etc. should be ready (3) Follow up inspection steps (refer to standard inspection report) in the factory workshop and warehouse. (4) Issue inspection report and send to related parties for confirmation. (5) Monitor products loading. Notes: All above inspection procedures are working under the bright light and safe environment. |

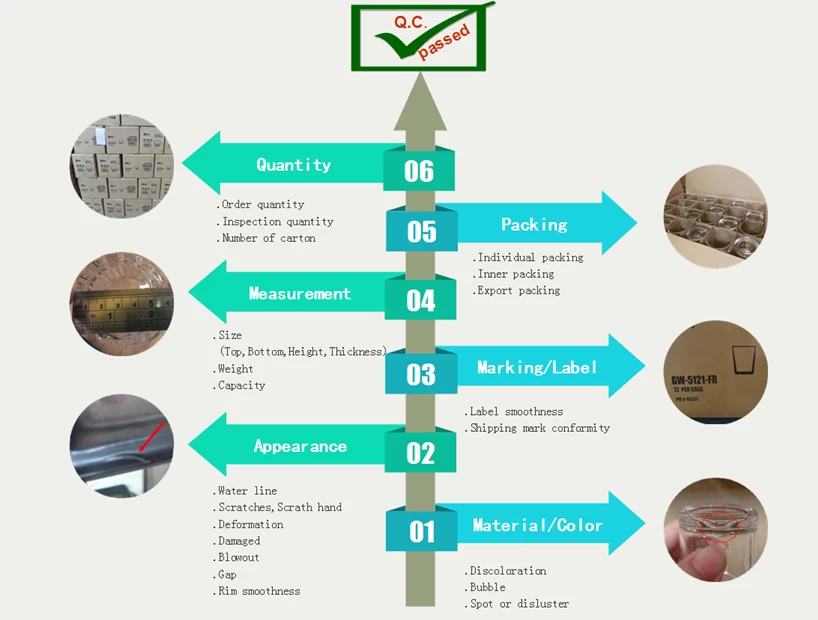

Inspection Points

Workmanship appearance Workmanship appearance |

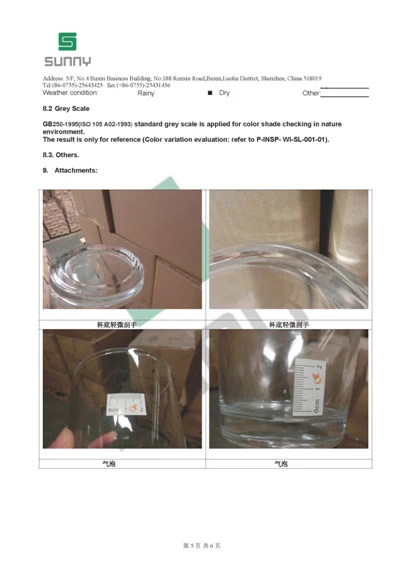

. Water line . Scratches, Scrath hand . Deformation . Damaged . Blowout . Gap . Rim smoothness |

Style/material/color Style/material/color |

. Discoloration . Bubble . Spot or disluster |

|

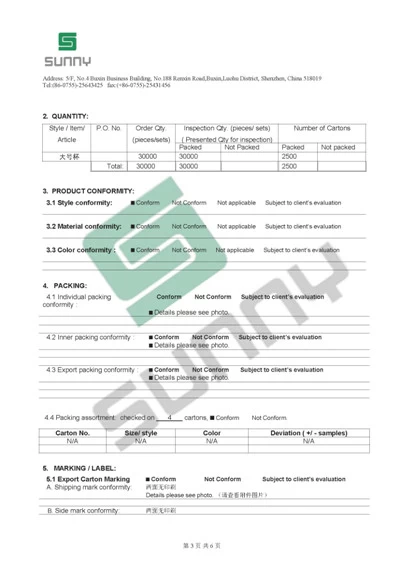

function/field tests |

. Measurement (Top,Bottom,Height,Thickness) |

Marking/label Marking/label |

. Label smoothness . Shipping mark conformity |

Packing Packing |

. Individual packing . Inner packing .Export packing |

Quantity Quantity |

. Order quantity . Inspection quantity .Number of carton |

Illustration

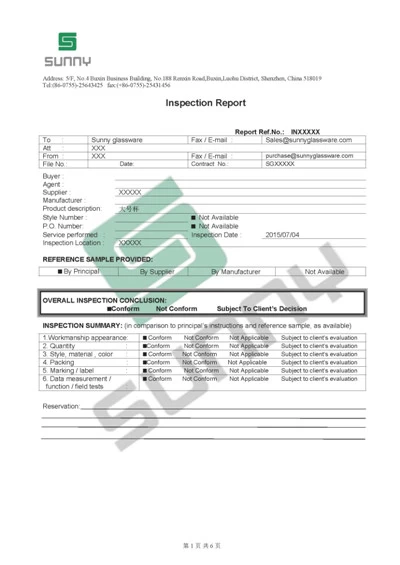

Report Template

|

|

|

|

|

|